After writing the last (rather hand-wavy) post on the idea of using fields to grow exotic conductor structures, I found a paper on someone doing this sort of thing for real, using silver nanowires:

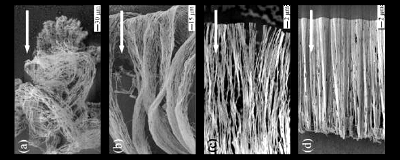

After writing the last (rather hand-wavy) post on the idea of using fields to grow exotic conductor structures, I found a paper on someone doing this sort of thing for real, using silver nanowires:- "A technique for controlling the alignment of silver nanowires with an electric field"

Yang Cao et al 2006 Nanotechnology 17 2378-2380 doi: 10.1088/0957-4484/17/9/050

- "Electric field can align silver nanowires"

PhysOrg.com May 17th, 2006

Brick walls can learn

Another (slightly random) example of materials "memorising" and recreating the effect of an applied potential is what happens to an external house-wall when your guttering is leaky.

Suppose that rainwater runs down the outside of your house and creates a bit of a damp patch on the inside wall. If the patch is bad, it's tempting to try to dry this out quickly from the inside by training a blow heater on the offending splodge. You evaporate the water at the surface, more water moves in from within the wall to take its place by capillary action, and you hope that at some point, the process will stop. You hope that you'll dry out the surface deeply enough that the rest of the water will stay put, somewhere deep within the wall, and perhaps dissipate. Some of it might work its way to the inside surface over a larger area and evaporate slowly and less intrusively, and some of it might eventually find its way back to the outside, the same way it got in. You hope.

But damp spots on walls are pesky creatures ... if you remove the surface water from one place too "aggressively", you're encouraging moisture directly below that section of surface to seep in to take its place faster than the usual seepage rate. In the worst-case scenario, instead of water slowly spreading through the wall in all directions, you're creating a faster directional flow within the wall, with water from a wider region of brickwork and plaster all converging on the extraction point where your heater is trained ... and as it moves, it dissolves salts and minerals from the wall and deposits them where the water is being driven off. If you see a crusty surface deposit forming, you're in trouble – it means that all that material has been dissolved out of the wall, possibly from around the points of greatest proportional resistance to the directional flow that you've created. You've etched a series of tiny micro-channels into the wall that converge on your extraction point, as a microscopic three-dimensional counterpart of how rivers carve channels into their landscape.

There might also be a concentration of those salts and minerals within the wall, towards the extraction point. If that happens, then the water-loving salts have created an absorbency gradient within the wall that represents the original flow, and once that piece of wall has dried out, if the dried region butts up against a damper region, the more "salty" part of the wall will draw water into it preferentially. The water will continue moving preferentially towards the most absorbent neighbouring region, following the original gradient ... straight back to your dried-out patch. So what you've done is (1) optimised the wall microstructure to collect water from a large area and direct it towards your extraction point, and (2) created an absorbency gradient in the wall to attract and hold the moisture and recreate the original damp patch. You've trained the wall to take water from the outside and carry it to the exact point on the inside where you didn't want it!